Finite Element (FE)

simulation is an engineering discipline that is applied in various ways in

industries such as aerospace, automotive, power train, customer goods and bio-engineering. It is commonly used to augment experimental testing to save

time and money at different stages in the product development process. More

recently, FE simulation is gaining ground in the field of Additive

Manufacturing to optimize and verify designs, or to simulate the AM process

itself.

Compared to traditional manufacturing procedures, AM allows for great

design freedom to produce complex and organic shapes enabling designers and

engineers produce designs that are very light while meeting structural integrity

requirements. To check requirements for service of very complex designs

produced by AM is often an impossibility based on experience and becomes quite

expensive if one has to do several test prints for experiments. Here, FE

simulation comes in handy to check a designs’ suitability for service before a

single cent was spent on the manufacturing process.

In most mid- to large-size companies it is quite common to have access

to commercial FE tools to optimize and check the suitability for service of

designs. However, in the Additive Manufacturing service industry access to

commercial simulation software may be limited or not possible due to a various

reasons. But what can one really do if they want use FE simulation to improve

their designs without having the opportunity to use commercial FE software?

Open Source Software has nowadays spread globally for pretty much all

application needs, and luckily, also for Finite Element simulation. There are

various websites that list comprehensively available Open Source FE software

such as the one from opennovation. For structural

simulation, and considering my Abaqus background, I have found the Open Source

FE software Calculix very convenient and

helpful to address a broad range of my simulation needs. To illustrate some of

Calculix’s structure-mechanical simulation functionality, I took the winner

design of the GE

Bracket challenge for Additive Manufacturing and generated a FE model to

determine the von Mises stress distribution. In addition to that, I ran the

same model with Abaqus

to demonstrate eventual differences in results between the Open Source and the

commercial FE software.

1.

In a first step I used the open source meshing software NETGEN to create

the FE mesh with 2nd order tetrahedral elements and to specify surfaces that

will be used for defining boundary conditions.

2.

Then I exported the model as INP file (Abaqus nomenclature) and manually

created a job file to apply boundary conditions and define analysis steps.

Generating the job file manually may require some exercise. However, Calculix

comes with decent documentation and examples that will help you to better

understand the syntax.

3.

After preparing the model and the job file I ran the analysis and

generated von Mises color plots.

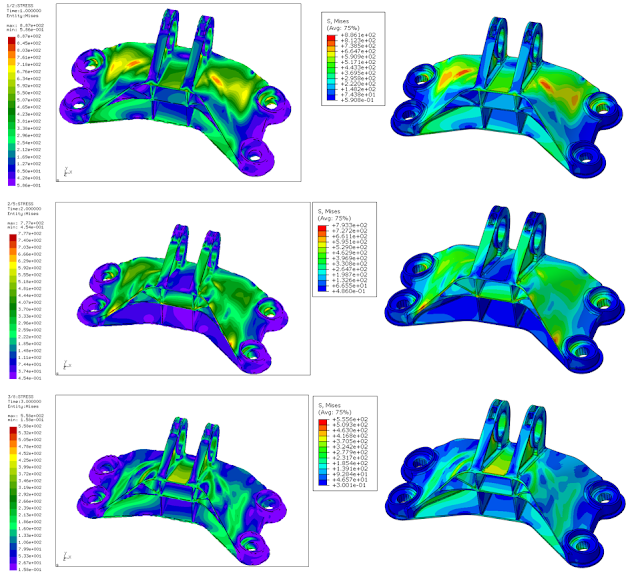

The following plots show the von Mises stresses for the first three

loading scenarios:

The maximum von Mises

stresses in the Calculix version (images left) and the Abaqus version (images

right) are as follows:

Calculix

[MPa]

|

Abaqus

[MPa]

|

Difference

[%]

|

887

|

886

|

0.11

|

777

|

793

|

2.02

|

558

|

557

|

0.18

|

The comparison of the

von Mises stresses and their location showed that there is almost no difference

between the results of the Open Source and the commercial software. The biggest

difference occurs in the 2nd load case and is about 2%.

So, what is the

conclusion about this exercise? In this article I wanted to raise awareness

that there are accessible, alternative options to commercial FE software tools

if you want to optimize and check the suitability for service of designs e.g. via

maximum stress levels. There are of course downsides to free software tools;

commonly they are not as well supported as commercial ones, they may not

include the latest technology and methodologies or include other issues that

may raise the end-users’ concerns. Nevertheless, I found that for

structure-mechanical applications Open Source software such as Calculix works

very well and presents a great, low-cost alternative to commercial software to

investigate the integrity of designs.

If you have thought

that you want to share on this article, please leave a comment or send me a

message.